|

| Springfield Armory “Long Beach” Model Ready for Duty |

Recently, a K-9 officer I had worked with when I was a Gang Detective purchased a Springfield “Long Beach” Operator model 1911. This model is was made at the request of Long Beach (CA) PD officers who essentially wanted an MC Operator but in an all black package. It is built with higher grade parts (and workmanship) than the typical “Loaded” model pistols, and is pretty close to being ready for duty. However, it still needed some intervention by skilled hands before it was ready for duty.

At a recent 10-8 Duty 1911 (Transition) course, this pistol could not pass the 10-8 Function Test Protocol. The factory extractor would not hold tension, and had to be replaced with a Wilson Bulletproof unit. Once the new extractor was fitted, it was good to go until the gun got hot and dry. Then it would hang up in the feed cycle. The owner asked me to look it over and I agreed.

The first thing I did was check headspace, which was in spec. Then I ran a Manson Finishing Reamer, which will recut the chamber to SAAMI spec. I have yet to drop this reamer in a factory barrel and not have it remove metal. In my opinion, this is cheap insurance to help the gun chamber and lock up when hot, dry and dirty. I looked at the barrel throat and saw it could use a little reprofiling. While I gave it a pretty high polish, this is not necessary. It is critical to have correct geometry as no amount of polishing will fix poor feed ramp or barrel throat geometry.

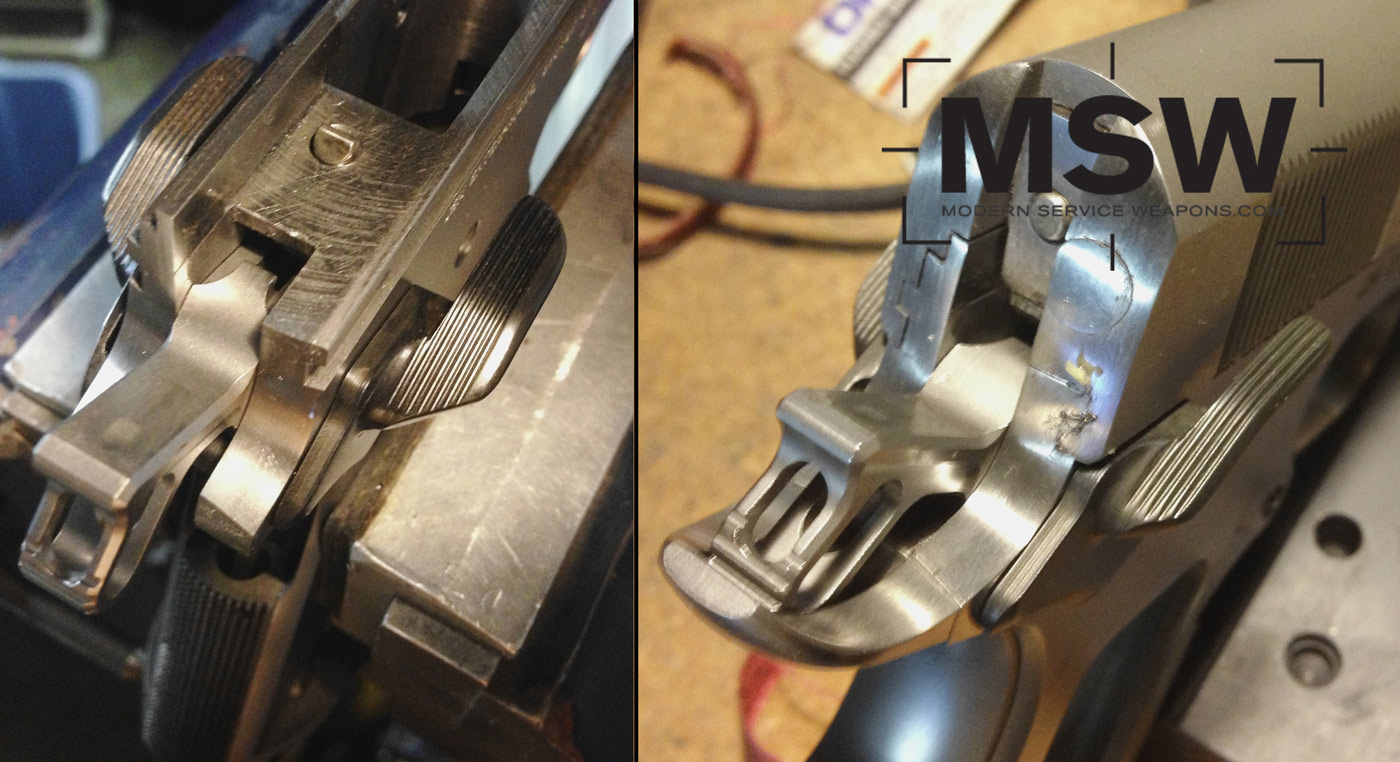

Here is what the throat looked like prior to reprofiling.

Here it is after:

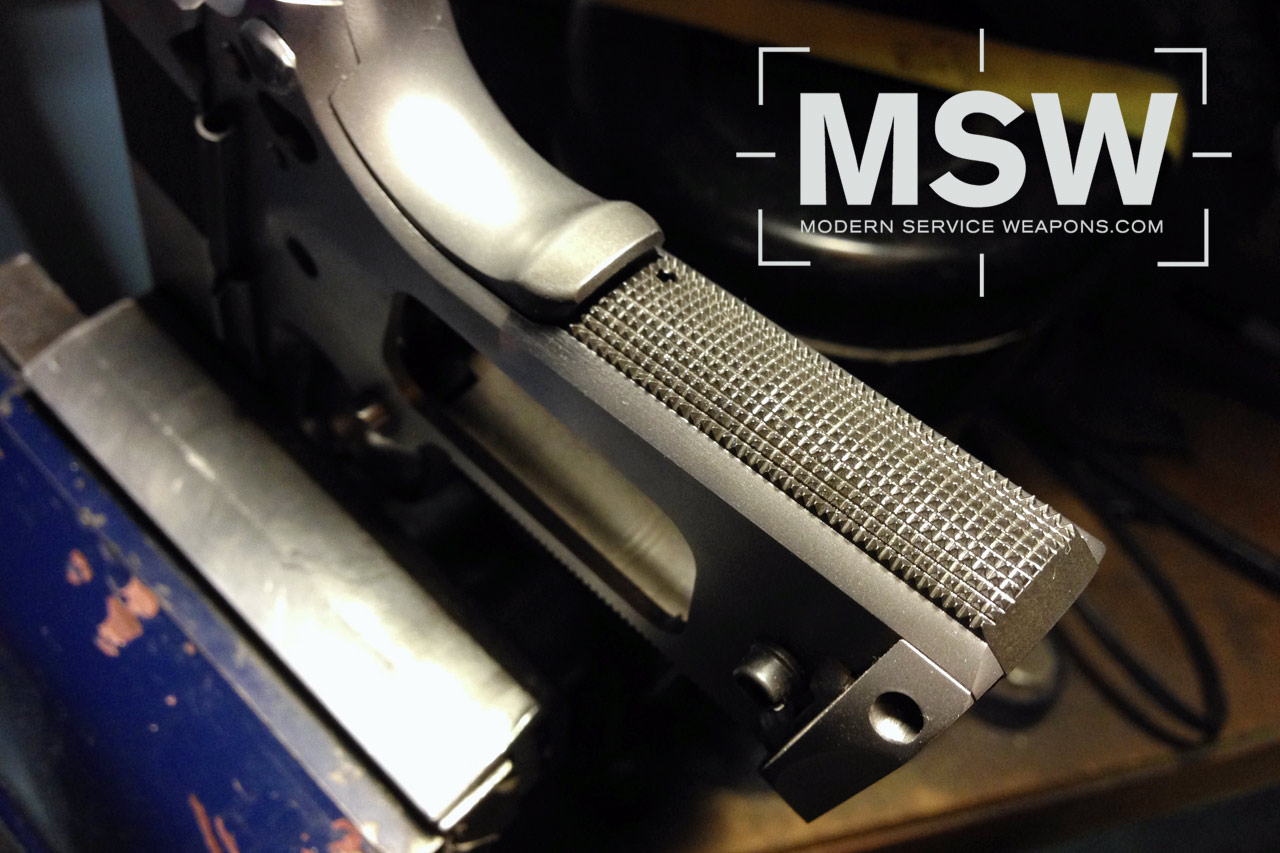

One look at the feed ramp and it was obvious it was out of spec. The bottom of the ramp should be around .400″ below the top of the frame rails. An easy way to eyeball this is to see if the bottom edge feed ramp is about even with the window for the slide stop lobe. As seen in the photo below, this one wasn’t even close. You can get away with this if all you shoot is ball ammo, or non-aggressive hollow points, but if you want to shoot a variety of aggressive bullet profiles, this is a recipe for a feed way stoppage.

Here is the same frame after the feed ramp is recut and polished. Again, the polishing is really a feel good measure, and not important. Much more critical is the proper angle. Since I lack machines, this feed ramp was recut by hand with a Dremel. Polishing was carefully done by hand with paper and then a felt wheel.

Other mods include changing out the torn head grip screws with flat head ones (I don’t carry torx drivers with me on the range) and relieving the grip panels to exposed the MSH pin. This particular pistol did not have enough trigger travel rearward to clear the sear for the safety shelf. Without going into a long treatise, this is a dangerous situation that could result in a broken sear nose. In this case, I had to clearance the grip safety arm as the trigger bow was running into it.

A couple hours of work and the pistol was ready for test fire. It passed the 10-8 1911 Function Test Protocol with flying colors. I am confident that with the proper preventative maintenance cycle, and good magazines, this pistol should serve its new owner well for many years to come.

Tim L

10-8 Consulting, LLC